Description

gas Polyethylene pipes have many applications in the oil and gas and petrochemical industry, the most important of which is the use for gas transmission with very large volumes and between cities, perhaps the most important advantage of polyethylene gas pipes is long resistance to heat (up to 95 degrees Siliceous) and corrosion.

Mehravand company, according to its big goal setting, succeeded in entering the list of suppliers of National Gas Company of Iran in November of 2015. who achieved another honor for serving the ancient land of Iran.

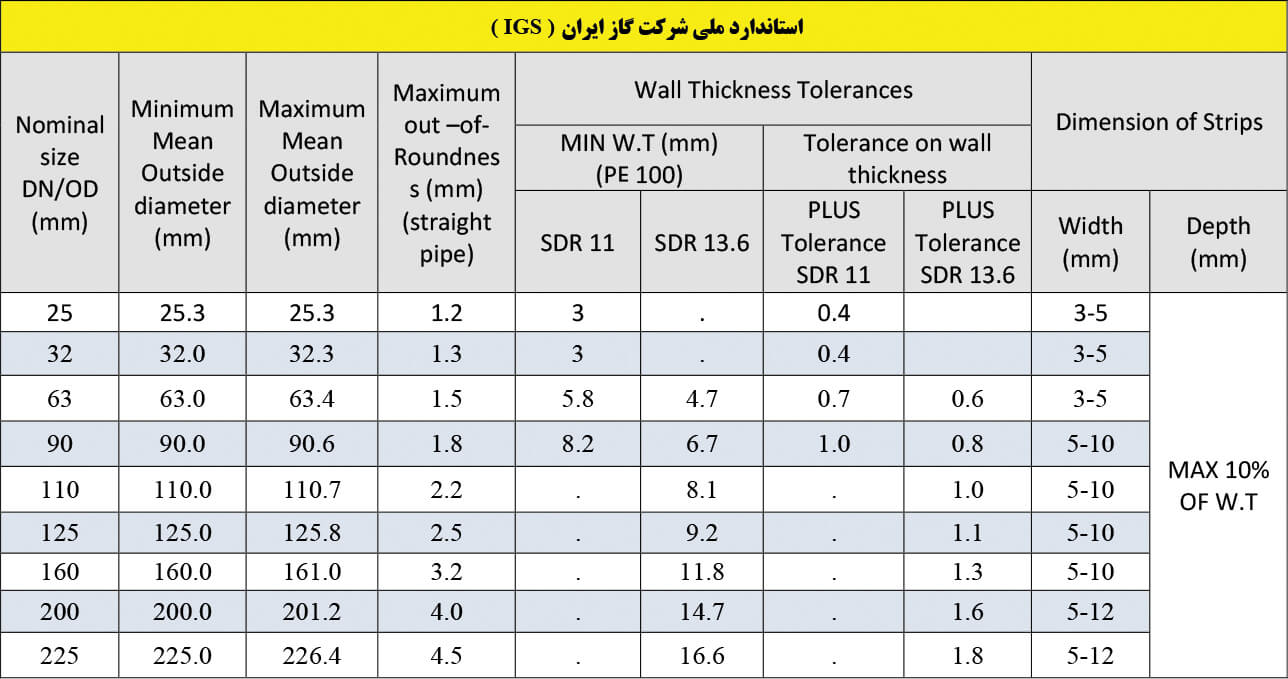

Due to the unique property of polyethylene material for use in gas supply pipes, these pipes are made from the best quality materials (PE100 color) and from 25 to 225 mm in diameter with SDR (11,13.6) based on the national standard IGS- M-PL-014-1(2) and international EN1555 are designed and produced, the company’s lines are equipped with an ultrasonic device, which allows the production personnel as well as quality control, with full control and supervision. Accurate on the weight per meter of manufactured pipes as well as the diameter and thickness defined in the standard range of each type and size of pipe to minimize the error in the weight per meter of pipe.

Polyethylene pipe for use in gas supply networks are produced by this company according to IGS-MPL-014-01(03)-EN1555 standards. And for a period of 50 years of continuous work, they are used for gas supply purposes. These pipes range from 25 to 225 mm gas polyethylene pipes, and the production lines of this company include the most modern European machines equipped with ultrasonic and gravimetric systems.

It should be mentioned that polyethylene gas pipes are made of high pressure polyethylene pipes or (HDPE).

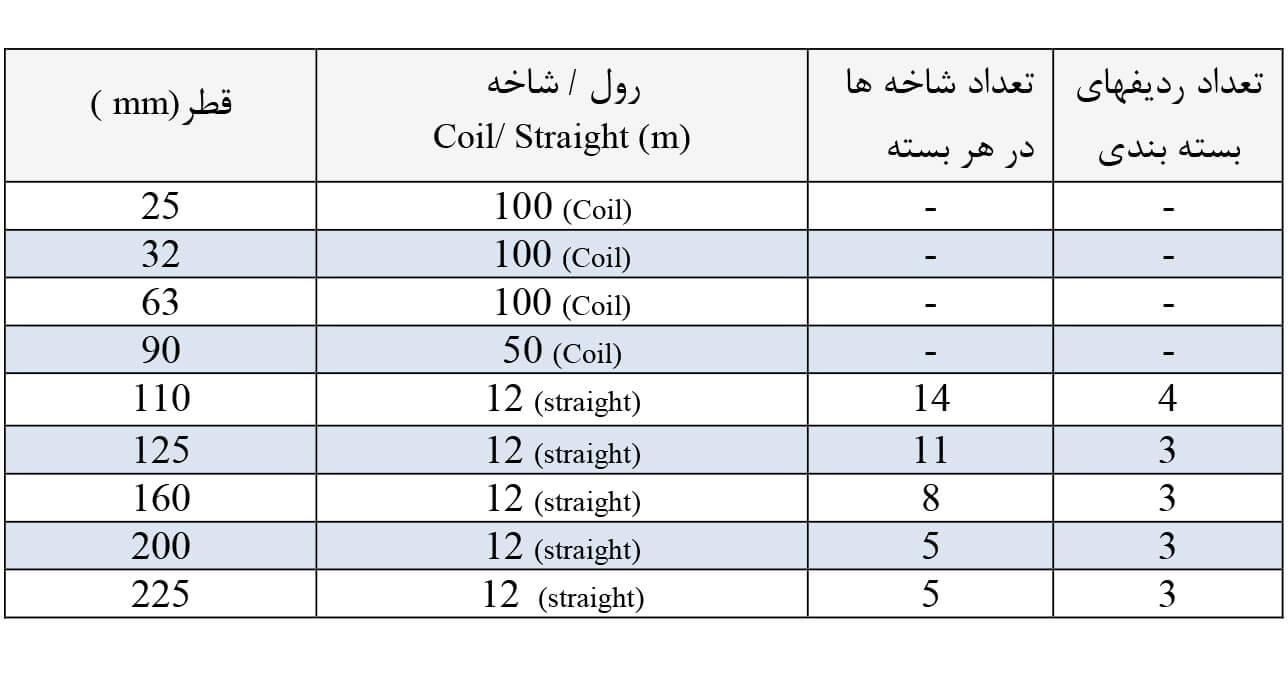

The storage, moving and transportation of polyethylene gas pipes in Mehravand company is done according to IGS-C-DN-006 (0) standard.

Branch pipes and rolls for packaging are based on this table:

Mehravand Mashhad Company is one of the best producers of gas polyethylene pipes in Mashhad:

Member of the EP website of National Iranian Oil Company

Member of vendor list of Iran Gas Company

Gas standard incentive certificate No. 11233-1 and 2

Certificate of approval of production companies from National Gas Company

Types of use of gas polyethylene pipes

Polyethylene gas pipes are used to transport all types of natural gas, liquid gas (LPG), propane gas and domestic gas supply.

Advantages of using gas polyethylene pipes

Polyethylene pipes have many advantages, but we will focus on the most important ones here

1. Long life of the pipe

Polyethylene gas supply pipe has a lifespan of between 50 and 100 years, and this means reducing the cost of maintenance and repairs

2. Resistant to corrosion and the effects of chemical and physical substances

Gasification polyethylene pipe has a very high chemical resistance, it is very resistant against chemical compounds, rodents and alkaline fluids.

3. The high flexibility of gasification polyethylene pipes

Polyethylene gas supply pipes can be bent up to 25 times the diameter of the pipe, which means that in many cases there is no need to connect to change the angle of the pipeline. On the other hand, the flexibility of polyethylene gas supply pipes can be justified in earthquake prone areas Is.

4. Easy connections of gasification polyethylene pipes

Gas polyethylene pipes are easily connected to each other, this is if other gas supply pipes are difficult to connect and usually have high leakage, this advantage is very important in the transmission of high pressure lines.

5. Affordable price compared to steel pipes

Low price of gas polyethylene pipes

6. Ability to squeeze gas polyethylene pipes

It is possible to squeeze gas polyethylene pipes during the implementation of the project if there is a defect

Polyethylene gas supply pipe of Mehravand Mashhad company

Disadvantages of gas polyethylene pipes

In general, polyethylene pipes do not have any special disadvantages, but we will mention a few of them below

1. The gas polyethylene pipe may get damaged and scratched during moving, which is why gas pipes have special packaging.

2. Polyethylene pipes do not have anti-flammability properties, and during a fire, the fire on the pipe quickly ignites.

3. Pressure drop for a long time

Gas polyethylene joints

In general, there are two types of connections

Electrofusion welding

Butt fusion welding

The advantage of electrofusion welding

1. High flexibility

2. Easy and fast connection

3. High strength against earthquakes and landslides

4. Resistance to corrosion and chemicals

5. 100% insulation

6. The type of electrofusion fittings is PE100 and pressure class 16 bar and different sizes from size 20 to 250

Types of electrofusion joints

pipe by pipe

tube to knee

Pipe to Bublin

Butt fusion welding

In welding joints in butt-to-head welding, where special connectors called couplers with electrical resistance are used to create the necessary heat to melt the weld surface.

The price of gas polyethylene pipe or the price of gas supply polyethylene pipe

Polyethylene gas pipe of Mehravand company, from sizes 25 to 225, many people are looking for the price of polyethylene gas pipe, regardless of knowing that these pipes have different pressure and dimensions, which causes the price to increase or decrease. To choose the right polyethylene gas pipe, you can call the company numbers 05132221884 05132221984 or send a message on WhatsApp

Reviews

There are no reviews yet.